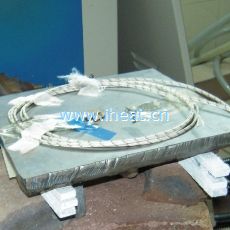

induction forging copper pipe (IGBT-100KW-10-30KHz ø10mm-20mm)

Views

Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced thermal distortion and damage.

This ability can be used in hardening to produce parts with varying properties. The most common hardening process is to produce a localised surface hardening of an area that needs wear-resistance, while retaining the toughness of the original structure as needed elsewhere. The depth of induction hardened patterns can be controlled through choice of induction-frequency, power-density and interaction time.

This ability can be used in hardening to produce parts with varying properties. The most common hardening process is to produce a localised surface hardening of an area that needs wear-resistance, while retaining the toughness of the original structure as needed elsewhere. The depth of induction hardened patterns can be controlled through choice of induction-frequency, power-density and interaction time.

PDF: induction forging copper pipe (IGBT-100KW-10-30KHz ø10mm-20mm)

Good

Bad

Related Content

surface induction heating aero material

induction Zone Heating for Bending

induction Wire Heating

induction heating in Magnetically Induced Hyperthermia for Cancer

induction heating gear

inducdtion heating screws

high frequency induction jointing

induction Epitaxial growth of silicon(IGBT-100KW-20KHz)

Newest Comment

No Comment

Post Comment