Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced thermal distortion and damage.

This ability can be used in hardening to produce parts with varying properties. The most common hardening process is to produce a localised surface hardening of an area that needs wear-resistance, while retaining the toughness of the original structure as needed elsewhere. The depth of induction hardened patterns can be controlled through choice of induction-frequency, power-density and interaction time.

Limits to the flexibility of the process arise from the need to produce dedicated inductors for many applications. This is quite expensive and requires the marshalling of high current densities in small copper inductors, which can require specialized engineering and 'copper-fitting'.

Chain heat treatment

flat induction coil for surface heating treatment_2

Large metal internal bore induction heat treatment

flat induction coil for surface heating treatment_1

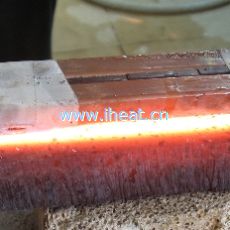

induction heating 12cm steel bar by 30KW

induction heating shears and knife

400mm clutch disc by induction heating treatment

Induction-Heat-Treatment-Services

Radio Frequency induction heating 46cm steel pipe

6 meters metal track induction heat treatment

Induction Heat treatment of larger objects

High-frequency electron tube by induction heating

Radio Frequency induction heating 46cm steel pipe Class: Induction Heat Treatment

Radio Frequency induction heating 46cm steel pipe Class: Induction Heat Treatment Intro: Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an

induction heating shears and knife Class: Induction Heat Treatment

induction heating shears and knife Class: Induction Heat Treatment Intro: Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an

Induction-Heat-Treatment-Services Class: Induction Heat Treatment

Induction-Heat-Treatment-Services Class: Induction Heat Treatment Intro: Induction-Heat-Treatment-ServicesInduction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction an