applications of HengXin induction heating machine

2004-6-4 From: Local Views

Various applications of HengXin induction heating machine

"We try to give our customers a clear idea of what induction heating is, and how this non-contact method of heating works so fast. The alternating current in the work coil sets up an electromagnetic field that creates a circulating current in the work piece. This circulating current in the work piece flows against the resistivity of the material and generates heat. It's really that simple!" - Dr. Xiao

Induction heating is a method of providing fast, consistent heat for manufacturing applications which involve bonding or changing the properties of metals or other electrically-conductive materials. The process relies on induced electrical currents within the material to produce heat. Although the basic principles of induction are well known, modern advances in solid state technology have made induction heating a remarkably simple, cost-effective heating method for applications which involve joining, treating, heating and materials testing. For details about using induction heating with non-conductive materials, please visit email to us.

--------------------------------------------------------------------------------

Components of a Typical Induction Heating System

The basic components of an induction heating system are an AC power supply, induction coil, and workpiece (material to be heated or treated). The power supply sends alternating current through the coil, generating a magnetic field. When the workpiece is placed in the coil, the magnetic field induces eddy currents in the workpiece, generating precise amounts of clean, localized heat without any physical contact between the coil and the workpiece.

--------------------------------------------------------------------------------

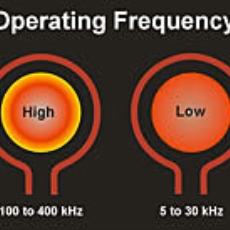

Operating Frequency

There is a relationship between the frequency of the alternating current and the depth to which it penetrates in the workpiece; low frequencies of 5 to 30kHz are effective for thicker materials requiring deep heat penetration, while higher frequencies of 100 to 400kHz are effective for smaller parts or shallow penetration. For heating microscopic parts, Ameritherm offers power supplies which operate at up to 60 MHz. The higher the frequency, the higher the heat rate; a good analogy is the act of rubbing your hands together for warmth. The faster your rub your hands together, the more warmth you produce.

--------------------------------------------------------------------------------

Magnetic Vs. Non-Magnetic Materials

Magnetic materials are easier to heat than non-magnetics, due to the effects of hysteresis heating. Magnetic materials naturally resist the rapidly changing magnetic fields within the induction coil. The resulting friction produces its own additional heat - hysteresis heating - in addition to eddy current heating. A metal which offers high resistance is said to have high magnetic "permeability". Permeability can vary on a scale of 100 to 500 for magnetic materials; non-magnetics have a permeability of 1. Hysteresis heating occurs at temperatures below the "Curie" point - the temperature at which a magnetic material loses its magnetic properties.

--------------------------------------------------------------------------------

Depth of Penetration

The induced current flow within the part is most intense on the surface, and decays rapidly below the surface. So the outside will heat more quickly than the inside; 80% of the heat produced in the part is produced in the outer "skin". This is described as the "skin depth" of the part. The skin depth decreases when resistivity decreases, permeability increases or frequency increases.

--------------------------------------------------------------------------------

Coupling Efficiency

Coupling refers to the proportional relationship between the amount of current flow in the workpiece and the distance between the workpiece and the coil. Close coupling generally increases the flow of current and therefore increases the amount of heat produced in the workpiece.

Heating Coil shape

|

|

|

|

|

|

|

|

Brazing

|

|

|

|

|

|

|

|

|

|

|

|

Metal smelting

|

|

Forging and rolling

|

|

|

|

|

|

|

|

Heat treatment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

More Applications

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Related News

applications of Hengxin induction heating equipment

Application of HengXin Induction Heating Machine

Motor Jointing with induction machine and EMS polymer glue

different induction heating applications

various induction coils for induction application

Applications of HX-05AB-UHF

application of HX induction heating equipment

Newest Comment

No Comment

Post Comment